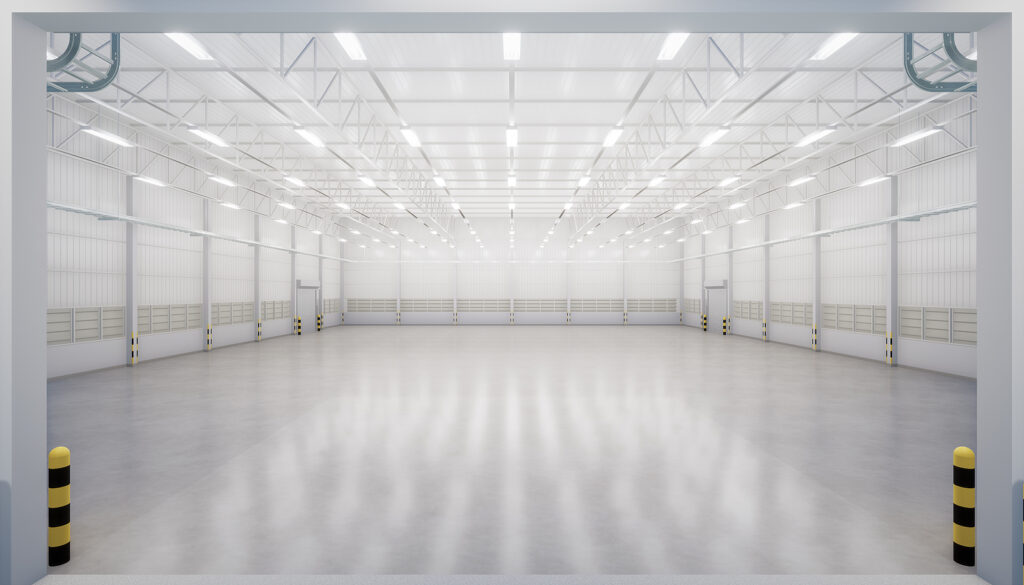

For many operations, their warehouse is one of their most important assets. If you see a lot of orders coming and going, you need a warehouse that is well-equipped to handle high volumes of traffic, while quickly picking up and moving goods as needed. This requires a great warehouse design – and a great warehouse lighting system to go with it.

Warehouses have a reputation for being poorly lit, but that’s bad business. A warehouse should be well-lit, to make it as easy as possible for workers to find and move stock while avoiding mis-picks and accidents. This calls for a warehouse lighting system with a lot of thought put into it.

At Hometown Electrical Services, we have decades of experience designing and installing work-friendly lighting systems across the Denver area. We’ll work with you to understand your needs and create a lighting system that supports your workers while minimizing waste.

These are the most important factors we always consider when implementing a warehouse lighting setup.

1. Brightness

Of course, overall brightness is one of the most important aspects, since every area of your warehouse must be visible. However, this is actually something of a balancing act, because too much light can also slow down workers. Plus, every extra watt of light will add to your electric bill, so long-term costs must be considered as well.

We consider the reflectivity of the walls and other interior objects, as well as how much natural light the warehouse gets, and choose lighting systems with the perfect balance of light output vs performance and ongoing costs.

2. Avoiding Glare

Glare can seriously sap productivity in a warehouse. In some cases, it can potentially even cause safety issues – such as glare distracting a worker driving a forklift or cherry-picker. This is another critical factor to consider, and a good Denver commercial electrical service will spend a lot of time with light meters testing areas within the warehouse to ensure glare is minimum.

3. Choosing an Optimal Color Temperature

“Color temperature” refers to how red (warm) or blue (cold) the light levels are. This affects visibility, and certain color temperatures can encourage – or prevent – eye strain among workers using the lights.

Typically, a color temperature of 4000K-5000K is seen as best for warehouses and other working environments. This range is tinted slightly blue and is close to natural sunlight, making for a comfortable lighting environment, but without going so far into the blue range that it can strain the eye.

That said, reflectivity within the warehouse can affect perceived color temperature, so it’s important to consider how the lights will look while in use, not just their listed color temperature.

- Light Distribution

There are various patterns of light fixtures that distribute light in different ways, depending on a room’s lighting needs. The most common light distribution types in warehouses are either Type I or Type V.

Type I creates long and narrow bands of light, which are necessary in warehouses with a lot of tall shelves and cramped ‘corridors’ between them. You need angled light which is capable of getting into those tight spaces and ensuring your warehouse workers still have clear visibility, even when they’re ‘boxed in,’ so to speak.

Type V is used for more wide-open warehouses with a lot of open space. It creates a wide spread of light, specifically intended to penetrate corners that may not have any lights directly overhead.

- Type of Lights

For decades, fluorescent bulbs were the standard in warehouses – and they’re still commonplace today. However, fluorescents do have their drawbacks. They’re relatively expensive, and don’t last as long as other alternatives. Also, many people consider the light they produce to be unpleasant or unnatural, leading to a slightly off-putting light situation.

Because of this, LED lights are becoming more common. LED lights give you a lot more flexibility when it comes to their intensity, hue, and color temperature. This makes it easier to fine-tune the overall look inside your warehouse.

In addition, LEDs are much more cost-efficient over time. Bulbs last far longer than alternatives, and they use far less power as well. They can bring you energy savings of up to 75% compared to other bulb types. Combined, this makes a very compelling case for installing LED lighting in your warehouse, even if the initial setup costs are a bit higher than alternatives. They will almost certainly pay for themselves many times over, in the long run.

- Number of Lights

Once you know the overall type of lighting you’ll need in your warehouse, the next step is to determine how many lights are called for. This is another area where minmaxing is the right idea. You don’t want to install too many light fixtures, since that adds to the costs, while doing little to improve the lighting situation since the lights will just overlap.

A great Denver commercial electrical service understands how various light fixtures interact with each other. They can look at your space and draw up a plan which will include the right number of fixtures – enough to fully light the space, without wasted purchases.

Hometown Electrical Services Can Design Your Warehouse Lighting System

Warehouse lighting is best determined and installed by experienced professionals. We have over 30 years’ experience serving the greater Denver area, including working with all types of commercial lighting systems. Our workforce is highly trained, and we focus on total satisfaction for every customer.

If you’re building a new warehouse and need excellent lighting to go with it, or you’re renovating an existing space that needs better lighting, Hometown Electrical Services has you covered! Contact us to discuss your needs and get a preliminary price quote.